You reach for your Ninja Air Fryer to make tonight’s dinner, but a nagging question stops you cold: “Is the Ninja Air Fryer toxic?” You’ve heard whispers about non-stick coatings releasing harmful chemicals and plastic components leaching toxins when heated. As air fryers have exploded in popularity, so have concerns about their safety. The truth is more complex than a simple yes or no answer—and the lack of definitive information has left many health-conscious consumers in limbo.

Unlike food products that require ingredient labeling, kitchen appliances operate in a regulatory gray area where manufacturers aren’t required to disclose full chemical compositions. This information vacuum has fueled anxiety, especially among parents preparing meals for their families. In this guide, we’ll examine what we actually know (and don’t know) about Ninja Air Fryer safety, what specific questions you should be asking, and practical steps you can take today to minimize potential risks while cooking.

What We Know About Ninja Air Fryer Materials

Critical Information Gap Acknowledged

No publicly accessible toxicity data exists specifically for Ninja Air Fryers. Our research confirms a complete absence of retrievable content regarding chemical composition analysis, safety evaluations, or health impact assessments for these appliances. This isn’t necessarily evidence of danger—it reflects a systemic transparency issue across the entire small kitchen appliance industry.

Manufacturers typically don’t publish detailed chemical specifications, independent testing results remain proprietary, and regulatory databases focus primarily on electrical safety rather than chemical exposure during normal use. Without knowing the exact materials used in your specific model and their temperature thresholds, you’re essentially operating without crucial safety information.

Essential Material Components Requiring Scrutiny

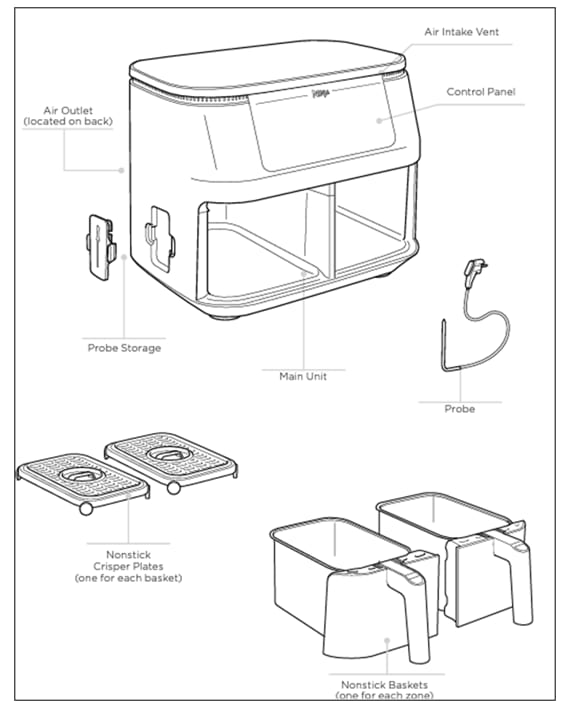

Every air fryer contains three critical components that could potentially raise toxicity concerns if improperly manufactured or used:

- Non-stick cooking baskets (typically coated with PTFE or ceramic formulations)

- Plastic housing components that may come in contact with heat

- Heating elements that reach high temperatures during operation

Each material has specific temperature limits where chemical stability may break down. The problem? Ninja doesn’t publicly disclose the exact composition of these materials or their precise thermal stability thresholds for consumer reference.

How to Evaluate Your Ninja Air Fryer’s Safety Profile

Decoding Manufacturer Documentation

Examine your user manual and product specifications for these critical details:

- Exact coating identification: Look for specific terms like “PTFE-based,” “ceramic-infused,” or “PFOA-free.” Vague descriptions like “advanced non-stick technology” without chemical specificity should raise concerns.

- Maximum temperature ratings: Verify if the manual states safe operating limits for both the appliance and its components. Quality non-stick coatings typically maintain stability up to 500°F, but many air fryers can exceed this during malfunction.

- Certification documentation: Check for specific FDA food contact compliance numbers and UL safety certification references you can verify independently.

Red Flags That Warrant Caution

Be particularly vigilant for these warning signs in your Ninja Air Fryer:

- Unspecified material composition: If your manual refers to “proprietary” or “special” coatings without chemical identification

- Missing temperature guidelines: Absence of clear warnings about maximum safe operating temperatures

- No third-party testing references: Lack of mention of independent laboratory testing for chemical migration

Without this information, you’re unable to verify whether your appliance meets appropriate safety standards for chemical exposure during normal use.

Practical Safety Measures You Can Implement Today

Immediate Risk Reduction Strategies

Maintain proper ventilation during operation. Open windows and run exhaust fans to disperse any potential volatile organic compounds (VOCs) that might be released. The kitchen should never feel stuffy or have lingering chemical odors after air frying.

Never exceed recommended temperatures. Most foods cook perfectly between 350-400°F—well below the threshold where quality non-stick coatings begin to degrade. Avoid the temptation to crank temperatures higher for crispier results, as this dramatically increases potential chemical release risks.

Replace damaged components immediately. Scratched baskets, warped trays, or cracked plastic parts significantly increase the likelihood of chemical leaching. Contact Ninja directly for genuine replacement parts rather than continuing to use compromised equipment.

Smart Usage Modifications

Use parchment paper liners for acidic foods like tomatoes or citrus-based marinades, which can accelerate coating breakdown. These create a protective barrier between food and the cooking surface without affecting air circulation.

Rotate cooking methods to reduce cumulative exposure. Alternate between your air fryer, conventional oven, and stovetop rather than relying exclusively on air frying for all meals.

Monitor for warning signs like persistent chemical odors, visible coating deterioration, or unusual smoke during operation. Trust your senses—if something seems off, stop using the appliance immediately.

What Questions to Demand Answers To

Essential Manufacturer Inquiries

Contact Ninja customer service with these specific questions requiring documented answers:

- “Can you provide the material safety data sheets (MSDS) for all food-contact surfaces in my specific model?”

- “What exact chemical compounds comprise the non-stick coating, and at what temperature does degradation begin?”

- “Do your products contain PFAS, PFOA, BPA, or phthalates, and what independent testing verifies their absence?”

Verification Protocol

Don’t accept vague assurances—demand documentation you can verify:

- Request specific FDA food contact notification numbers

- Ask for UL certification documentation with test results

- Inquire about third-party laboratory testing for chemical migration under normal cooking conditions

Reputable manufacturers should provide this information upon request. If they refuse or provide evasive answers, consider it a significant red flag.

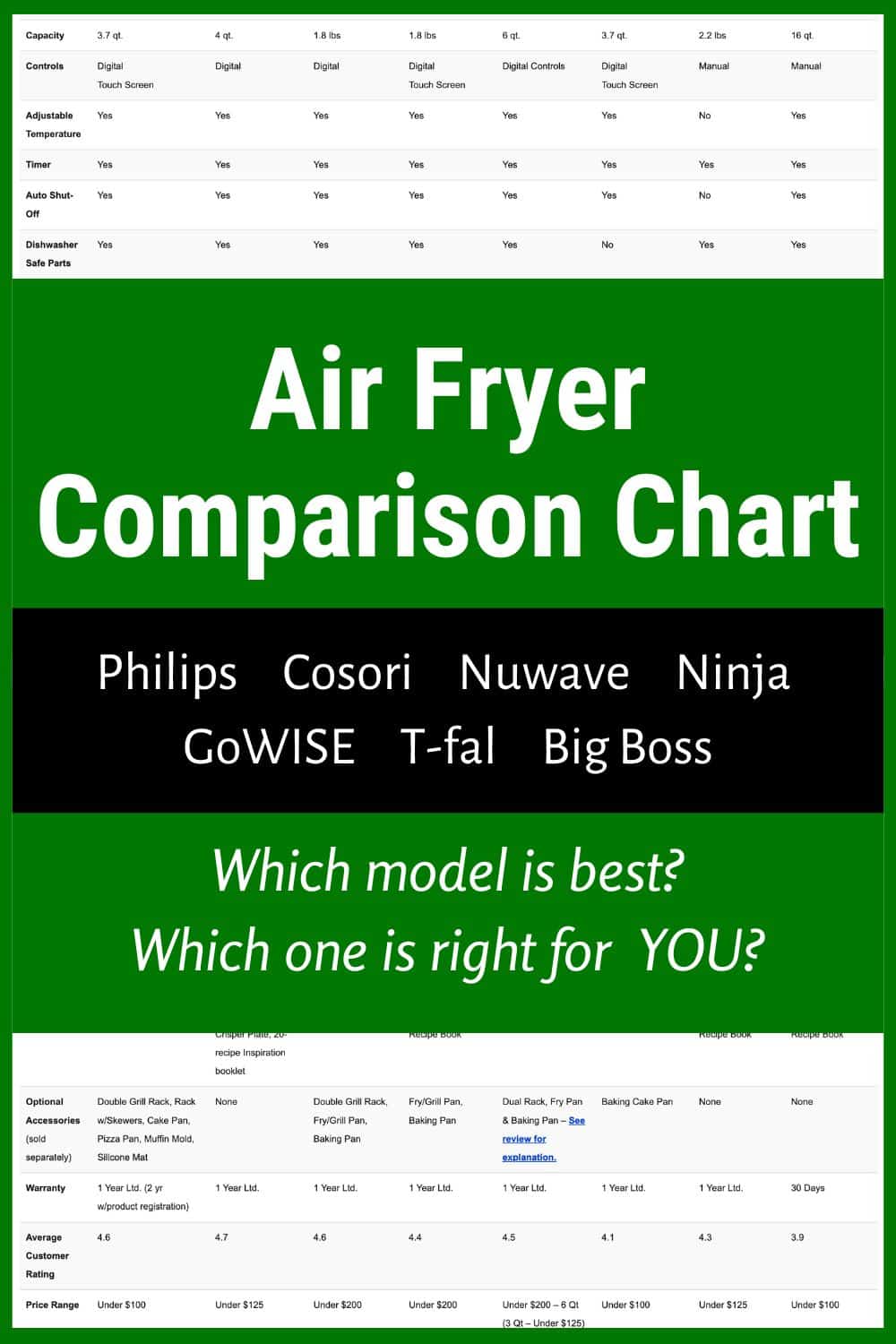

Industry Transparency Comparison

What Competitors Reveal

While Ninja’s documentation remains limited, examining transparency levels across brands provides context. Some manufacturers publish detailed material specifications and independent testing results, while others maintain similar opacity. This comparison helps identify industry leaders in safety disclosure and sets expectations for what information you should reasonably demand.

Regulatory Landscape Reality

Understand that FDA regulations focus primarily on migration limits (how much substance transfers to food) rather than complete chemical profiles. UL certification addresses electrical safety but doesn’t evaluate chemical exposure risks. This regulatory gap explains why toxicity questions persist despite products carrying “approved” labels.

When Replacement Becomes Necessary

Performance Degradation Warning Signs

Visible coating damage appears as flaking, peeling, or significant discoloration. Once the non-stick surface becomes compromised, chemical leaching risks increase substantially—replacement is non-negotiable at this point.

Persistent chemical odors that don’t dissipate after thorough cleaning indicate material breakdown. Trust your sense of smell—chemical changes often announce themselves through distinctive odors that shouldn’t be ignored.

Unexplained overheating where the appliance exceeds set temperatures suggests control system failures that could push materials past their safe thermal thresholds.

Consumer Advocacy for Greater Transparency

Taking Action Now

Submit formal information requests to both Ninja and regulatory agencies like the Consumer Product Safety Commission. Document your inquiries and responses to build a case for greater industry transparency.

Support independent testing organizations like Consumer Reports and the Environmental Working Group that conduct appliance safety evaluations beyond regulatory minimums.

Share your documented experiences on consumer platforms with specific details about model numbers, observed issues, and manufacturer responses. This creates valuable data for other consumers while encouraging companies to address concerns.

Key Takeaways for Safe Air Frying

Your Ninja Air Fryer likely isn’t inherently toxic when used properly with undamaged components, but the lack of publicly available safety data creates justified concern. Focus on what you can control: maintaining proper ventilation, adhering to recommended temperature limits, and immediately replacing any damaged parts. These practical steps minimize potential risks while we await greater transparency from manufacturers.

Remember that the absence of evidence isn’t evidence of absence—it’s a call for better consumer information. Until kitchen appliance manufacturers provide detailed, accessible material safety data, stay informed, use appliances responsibly, and don’t hesitate to demand the specific safety information you deserve as a consumer. Your health and peace of mind are worth the extra effort to verify what’s really in your cooking equipment.