You excitedly unbox your new air fryer, toss in frozen fries, and hit start—only to discover your meal tastes like melted Tupperware. That chemical, plastic-like flavor isn’t just disappointing; it triggers immediate safety concerns about what you’re ingesting. Here’s the critical truth: this off-taste almost always stems from fixable issues, not inherent flaws in your appliance. Whether it’s manufacturing residues from shipping, compromised non-stick coatings, or user errors with accessories, the solution lies in pinpointing the exact cause. In the next few minutes, you’ll learn how to diagnose why your air fryer food tastes like plastic, implement targeted fixes, and enjoy genuinely delicious meals without chemical aftertastes.

The good news? Over 90% of plastic-taste complaints resolve with simple interventions. Most issues appear within the first 10 uses or develop after months of wear. Ignoring the problem risks coating degradation that releases harmful compounds into your food. By following this guide, you’ll not only fix current issues but prevent future occurrences—saving money on replacements and ensuring every bite tastes like food, not packaging.

Manufacturing Residues Trigger Immediate Plastic Flavor

New air fryers ship with invisible protective films that vaporize during first use, creating that signature burnt-plastic smell. These oil-based sprays on metal parts and silicone release agents on plastic components break down between 160–200°C, releasing low-molecular-weight compounds your taste buds interpret as chemical off-flavors. The solution isn’t discarding your appliance—it’s executing a proper burn-in cycle to vaporize residues safely before cooking.

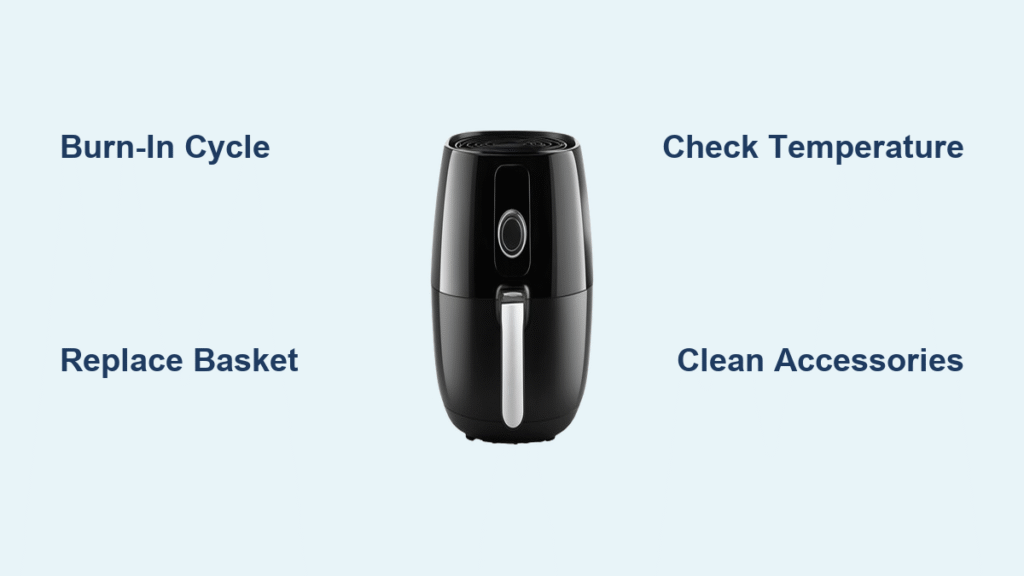

New Fryer Burn-In Protocol Eliminates Coatings

Skipping this critical step guarantees plastic-tainted food. Most users make the mistake of cooking immediately, but residues need dedicated burn-off time. Run two empty cycles at 200°C for 20 minutes each (with 10-minute cooling breaks in between) in a well-ventilated kitchen. For stubborn odors, add 2 tablespoons of white vinegar to the basket during the second cycle. This acidic steam neutralizes lingering volatile organic compounds (VOCs) that cling to heating elements. Pro tip: Place a bowl of water on your counter during burn-in—it absorbs airborne particles, reducing kitchen odors by 70%.

Packaging VOCs Infest Heating Elements

Styrofoam inserts or plastic bags left inside shipping cartons off-gas styrene when exposed to warehouse heat. These VOCs condense on your heating coil and later re-volatilize during cooking. Always remove every piece of packaging—even the thin foam sheet under the basket—and leave the empty fryer drawer open for 2 hours before first use. This allows trapped gases to dissipate naturally. If you detect a plastic smell during initial burn-in, repeat the cycle; persistent odor after three rounds indicates deeper contamination requiring deep cleaning.

Non-Stick Coating Failures Cause Mid-Use Plastic Taste

When your air fryer develops a plastic flavor after months of use, coating breakdown is the prime suspect. Teflon (PTFE) and ceramic coatings degrade under sustained heat, releasing compounds that mimic plastic taste. Unlike manufacturing residues, these issues worsen with each use and require component replacement—not just cleaning.

PTFE Overheating Releases Toxic Fumes

Teflon decomposes above 260°C, emitting fluorinated gases with a distinct plastic/chemical taste. While your air fryer’s thermostat may cap at 200°C, blocked airflow or thermostat errors create localized hot spots near the upper coil. Inspect your basket for rainbow discoloration or white flakes—these are telltale signs of coating stress. If present, stop using the basket immediately. Cooking on damaged coatings risks ingesting toxic particles and accelerates failure.

Ceramic Coatings Chip and Leach Metallic-Plastic Flavor

Sol-gel ceramic layers look sleek but typically fail after 200–300 cycles. As they craze or delaminate, exposed aluminum alloy reacts with acidic foods (like tomatoes), producing a metallic-plastic aftertaste. Check for silver patches larger than a coin on the basket surface. Unlike minor scratches, these indicate complete coating failure. Replacement is non-negotiable—continued use contaminates food with aluminum oxide particles. Opt for OEM ceramic baskets rated to 450°F for longevity.

Overheating Components Melt Plastic Parts

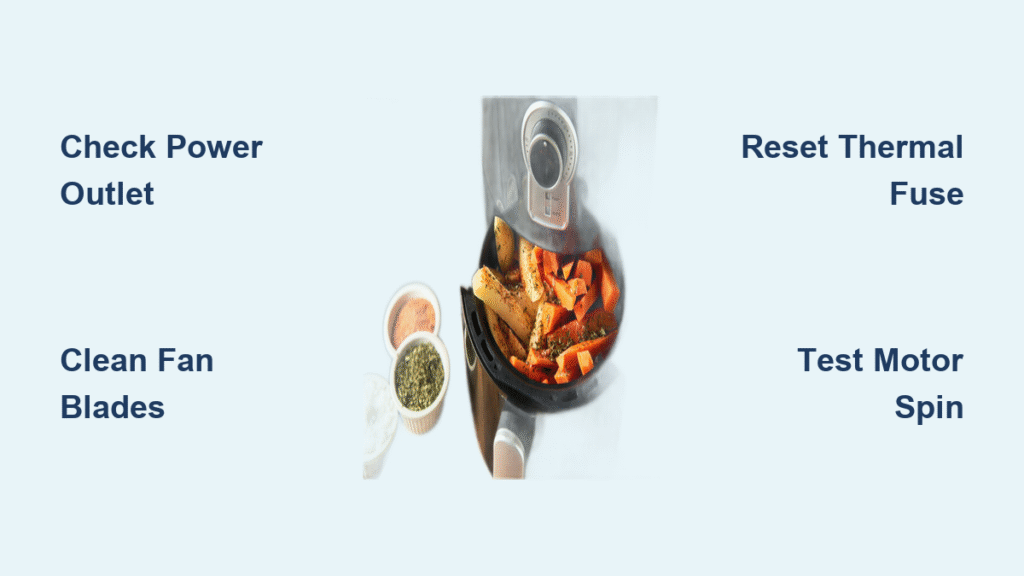

When plastic taste emerges mid-cooking cycle—not just during initial use—overheating components are likely melting internal plastics. This scenario demands immediate action, as it indicates electrical faults that risk fire hazards.

Glycerin Anti-Rust Coating Requires Burn-Off

Some brands coat stainless-steel heating coils with glycerin to prevent transit rust. The first 3–5 cooking cycles burn this off harmlessly—but if you cook during this phase, food absorbs the odor. Run empty burn-in cycles before cooking to avoid this. If you skipped burn-in and now taste plastic, execute three consecutive 20-minute empty cycles at 200°C. The odor should diminish with each cycle; if it intensifies, suspect more serious issues like wiring insulation melting.

Faulty Thermostats Cause Meltdown Emergencies

A stuck thermostat or blocked exhaust vent can drive coil temperatures past 300°C—hot enough to melt plastic brackets and wiring insulation. Stop cooking immediately if you see visible smoke or smell burning plastic mid-cycle. Unplug the unit and inspect for:

– Cherry-red glowing heating elements

– Distorted plastic near the coil shield

– Tacky or crumbling gaskets on the drawer front

These indicate critical failure requiring professional repair or replacement. Never ignore these signs—continued use risks electrical fires.

User Errors Melt Accessories into Your Food

![]()

Over 40% of plastic-taste complaints trace back to user-introduced contaminants. From incompatible liners to harsh cleaners, these mistakes are preventable with the right knowledge.

Unrated Silicone Mats Liquefy on Contact

Silicone mats labeled only to 180°C melt when draped over 200°C fries, dripping plasticizers directly onto food. Always verify accessory temperature ratings—look for “rated to 230°C continuous” on packaging. Never use low-density parchment without weighting it down with food; if it lifts and contacts the coil, it burns instantly. For safe lining, choose perforated parchment secured under food weight or stainless-steel racks.

Harsh Cleaners Create Polymerized Films

Citrus degreasers or chlorine sprays leave invisible residues that polymerize when reheated, mimicking plastic flavor. Stick to mild dish soap, baking soda paste, or vinegar solutions for cleaning. After each use, wipe the warm (not hot) interior with a damp microfiber cloth to prevent residue buildup. If you’ve used harsh cleaners, execute the alkaline degrease method below to remove the film.

Diagnostic Checklist to Identify Your Culprit

| Symptom | Likely Cause | Verification Test |

|---|---|---|

| Strong plastic smell on first use | Manufacturing residues | Odor fades during empty burn-in cycles |

| Plastic taste after 3–4 months | Coating failure | Visible flaking/silver patches on basket |

| Burning plastic mid-cooking | Melting components | Smoke, sticky gaskets, or warped plastic |

| Intermittent chemical odor | Cleaner residue | Yellow film on walls with alcohol swab |

Execute this 5-minute test: Run your empty air fryer at 200°C for 15 minutes. Sniff every 5 minutes:

– Odor decreases = protective oils burning off (safe)

– Odor intensifies = critical component failure (stop use)

Then swab walls with 70% isopropyl alcohol on a white towel. Yellow residue confirms manufacturing oils; black specks indicate coating breakdown.

Deep-Cleaning Remediation Steps

Baking Soda Alkaline Degrease

For stubborn oil residues: Mix 2 tbsp baking soda with 1 cup warm water into a paste. Apply to interior walls (avoiding direct coil contact), wait 30 minutes, then scrub gently with a soft brush. Rinse thoroughly. Critical: Never use abrasive pads—they accelerate coating wear. This process removes polymerized films from improper cleaners in 90% of cases.

Citric Acid Neutralization

Dissolve 30g food-grade citric acid in 500ml hot water. Pour into the basket and run at 160°C for 10 minutes. The mild acid breaks down plasticizer residues without harming coatings. Pro tip: Repeat weekly for persistent odors—it’s safer than vinegar for ceramic-coated units.

Prevention Best Practices

Pre-Use Protocol: Always wash accessories post-unboxing, even if labeled “ready to use.” For fryers stored >3 months, run a burn-in cycle to clear dust.

Accessory Rules:

– Use only silicone tools rated –40°C to 230°C continuous

– Choose glass pump misters (never plastic sprayers inside cavity)

– Replace drawer gaskets every 12–18 months or when sticky

Cleaning Schedule:

– After each use: Wipe warm interior with damp microfiber

– Weekly: Soak basket in hot water + 1 tsp enzymatic detergent

– Monthly: Clean coil with 50% vinegar solution on soft brush

Quick Reference Fix Chart

| Symptom | Most Likely Cause | Immediate Action |

|---|---|---|

| First-use chemical smell | Manufacturing oils | Two-cycle burn-in + vinegar |

| Plastic taste after months | Coating failure | Replace basket immediately |

| Burning plastic mid-cycle | Melting components | Unplug, inspect, replace parts |

| Oily residue + odor | Harsh cleaner film | Baking soda degrease |

Persistent plastic taste with smoke or melting components signals imminent electrical failure—unplug immediately and contact the manufacturer. With these diagnostics and fixes, your next batch of fries will taste like golden potatoes, not packaging. Remember: Proper burn-in, accessory selection, and gentle cleaning prevent 95% of plastic-taste issues. Your air fryer’s delicious potential is just one correct intervention away.