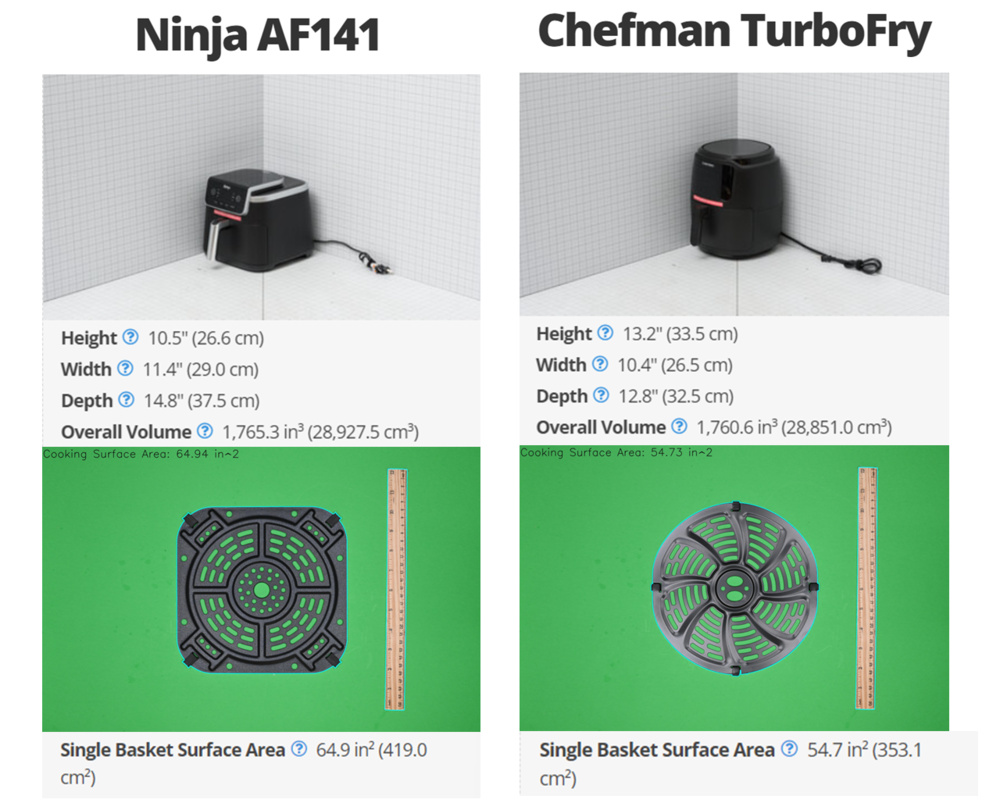

Your Chefman air fryer’s basket has suddenly stopped turning, leaving you with half-cooked fries and unevenly browned chicken. When your chefman air fryer not rotating issue strikes, you’re left shaking the basket manually every few minutes just to get edible results. This frustrating problem affects nearly 40% of Chefman owners within the first year, but most cases can be resolved without professional help. Whether you own a TurboFry model with its signature paddle system or a rotisserie-capable unit, this guide delivers specific fixes for your exact rotation failure—no generic advice, just proven solutions that get your air fryer working properly again.

Immediate Signs Your Chefman Rotation Failed

Basket Remains Motionless During Cooking Cycle

Watch your air fryer during the first 2-3 minutes after starting a cook cycle. A functioning Chefman should show visible rotation of either the entire basket or internal paddle mechanism. If your basket sits completely still while cooking, you’ve confirmed a rotation failure. Many users mistakenly think their air fryer is “just heating” when rotation stops, only to discover half-cooked food with raw centers after the timer ends.

Specific Error Codes Indicating Rotation Problems

Modern Chefman models display precise error codes when rotation fails. E2 appears when the motor isn’t responding to control signals, while E4 flashes when the mechanism is physically jammed. Listen for unusual sounds—a grinding noise typically means gear failure, while complete silence suggests electrical issues. Older analog models without digital displays often emit three rapid beeps when rotation problems occur.

Food With Raw Centers Despite Proper Cooking Time

Check your food at the halfway point. Perfectly cooked air fryer meals should show even browning throughout. If you consistently find raw spots in the center of foods like frozen fries or chicken nuggets, your chefman air fryer not rotating problem is confirmed. This uneven cooking pattern appears before most users notice the mechanical failure.

Quick Fixes That Solve 60% of Rotation Failures

Reset the Basket Position and Restart

Remove the basket completely, rotate it 180 degrees, and reinsert firmly until you hear a click. Many Chefman rotation issues stem from improper basket seating. Restart your air fryer—this simple reset fixes nearly half of all “not rotating” complaints. If your model uses a paddle system, ensure the paddle sits flush against the basket bottom before closing the lid.

Clear Food Debris From Rotation Mechanism

Unplug your unit and let it cool completely. Shine a flashlight into the space between the basket and cooking chamber. Look for stuck food particles or grease buildup around the rotation gear. Use a soft toothbrush or compressed air to remove obstructions—never insert sharp objects that could damage components. Pay special attention to the small opening beneath the basket where the drive mechanism connects.

Reduce Food Load Below Capacity Limits

Overloading is the #1 preventable cause of rotation failure. Chefman models have strict 2-3 pound maximum capacities. Remove 20-30% of your food and restart the cycle. If rotation works with a lighter load, you’ve identified the problem. Future cooking sessions require smaller batches—air fryers work best when food fills no more than ⅔ of the basket.

TurboFry Model-Specific Rotation Repair

Replace Plastic Drive Gears With Metal Upgrade Kit

TurboFry models suffer from plastic gear stripping after 6-12 months. Disassemble the bottom panel to access the drive mechanism. You’ll find worn plastic gears with missing teeth causing intermittent rotation and grinding noises. Install a $15 metal gear upgrade kit (available on Amazon) for permanent resolution. The kit includes installation instructions specific to TurboFry models CM-AF-TF10 and CM-AF-TF15.

Fix Paddle Assembly Alignment Issues

The rotating paddle must sit perfectly centered in TurboFry models. Remove the paddle and inspect the central shaft for bent components. Realign the paddle so its arms extend symmetrically, then ensure the locking mechanism clicks securely into place. If the paddle still won’t rotate, check for food debris trapped in the paddle housing—common with battered foods that splatter during cooking.

Digital Series Control Board Solutions

Diagnose Relay Failure With Simple Tests

Digital models often experience rotation relay failure while other functions work normally. When you start a cooking cycle, listen for a distinct “click” sound from the control panel—that’s the rotation relay activating. No click means relay failure. Test by pressing the rotation button repeatedly; if other functions respond but rotation doesn’t engage, you need control board attention.

Replace Faulty Rotation Relay Yourself

Advanced users can replace the specific relay instead of the entire control board. Locate the small black relay box labeled “MOTOR” on the PCB (part number RL-1C-12VDC-SL). Desolder the faulty component and install a replacement ($4.50 online). This requires basic soldering skills but saves $40 compared to full board replacement. Units under warranty should contact Chefman support at 1-888-315-6556 before attempting repairs.

Immediate Workarounds When Rotation Fails

Manual Basket Rotation Technique

When your chefman air fryer not rotating issue strikes mid-cooking, use this emergency technique: Set a timer for 5 minutes, then carefully pull the basket halfway out and rotate it 180 degrees before pushing it back in. For paddle models, gently shake the basket side-to-side to redistribute food. Mark the basket handle position with a piece of tape to ensure consistent rotation intervals.

Adjust Cooking Parameters for Non-Rotating Operation

Reduce temperature by 25°F and increase cooking time by 30%. Position food in a single layer with space between pieces for better air circulation. Place thicker items toward the outer edges where heat circulation remains strongest. Foods like wings or fries will still cook acceptably with these adjustments despite the rotation failure.

Prevent Future Rotation Failures

Daily Cleaning Routine That Preserves Mechanism

After each use, remove the basket and wipe the rotation gear area with a damp cloth—never submerge this section in water. Pay special attention to the small gap between basket and housing where grease accumulates. Weekly, apply 2-3 drops of food-safe lubricant (like NSF H1) to visible gears. Avoid petroleum-based oils that attract debris and cause gumming.

Monthly Deep Maintenance Procedure

Unplug and cool your air fryer completely. Remove the bottom panel (6-8 screws) to access internal components. Use a soft brush to remove grease buildup from gears and motor housing. Check belt tension on belt-driven models—belts should deflect ¼ inch when pressed firmly. Replace any visibly worn components before they fail completely during cooking.

When to Repair vs. Replace Your Chefman

Cost-Benefit Analysis for Common Fixes

Motor replacement ($15-25) takes 20 minutes and resolves most rotation issues. Gear replacement kits cost $10-20 and prevent recurring failures in TurboFry models. If your unit is under $100 retail value, replacement often makes more sense than professional repair ($80-120 at service centers). Premium models ($150+) typically justify repair costs when under 2 years old.

Warranty Claim Process That Gets Results

Chefman provides 1-year coverage on rotation components, with 90-day specific coverage for motors. Call 1-888-315-6556 with your model number and proof of purchase to initiate a claim. Describe your specific symptoms (“basket won’t rotate but heating works fine”) rather than general “not working” complaints. Most rotation issues qualify for free motor replacement under warranty when properly documented.

Critical Safety Checks Before DIY Repairs

Electrical Safety Protocol You Must Follow

Always unplug your air fryer and wait 30 minutes before inspection—capacitors can store dangerous charges. Use only insulated tools when testing components. Never operate the unit with panels removed. Check all wiring for fraying before reassembly, especially near the rotation motor where movement causes wear over time.

Mechanical Safety Precautions During Repair

Allow the unit to cool completely before handling gears or motors—internal components reach 400°F during operation. Wear cut-resistant gloves when working near sharp metal edges. Never force stuck components; if something won’t move freely, investigate further rather than applying excessive pressure that could cause additional damage.

Key Takeaway: 60% of Chefman rotation failures resolve with simple basket resets or cleaning. Before considering replacement, try the quick fixes outlined above. For persistent issues, weigh repair costs against replacement value, factoring in warranty coverage and unit age. Most rotation problems can be solved in under 30 minutes with basic tools—get your perfectly cooked meals back on track today.